Product description

S1012N cut resistant gloves are made of high-density polyethylene and nitrile material, providing excellent durability and protection. The nitrile coating can be made not only in grey, but also in customized colors to meet the needs of different working environments. The gloves are designed with attention to detail to ensure maximum protection while maintaining comfort and dexterity.

Main Features

1. **CUT RESISTANCE**: HDPE material has excellent cut resistance, which can effectively protect the hand from sharp objects.

2. **Tear Resistance**: The high strength material and structural design of the gloves provide good tear resistance and prolong service life.

3. **Abrasion Resistance**: Nitrile coating enhances the abrasion resistance of the gloves, making them suitable for use in high abrasion environments.

4. **Slip Resistance**: The black nitrile coating on the palm section provides excellent slip resistance and maintains a good grip in dry, wet and greasy environments.

5. **OIL RESISTANCE**: Nitrile material has good oil resistance and is suitable for use in oily environments.

6. **High elasticity**: the gloves have good elasticity, which can adapt to different hand shapes and provide a comfortable wearing experience.

7. **Flexible**: the flexibility of the material allows the gloves to provide protection without affecting the dexterity of the hand.

8. **DURABLE**: High-quality materials and fine manufacturing process ensure the durability and long service life of the gloves.

9. **FIT**: The gloves are ergonomically designed to be comfortable to wear and reduce hand fatigue.

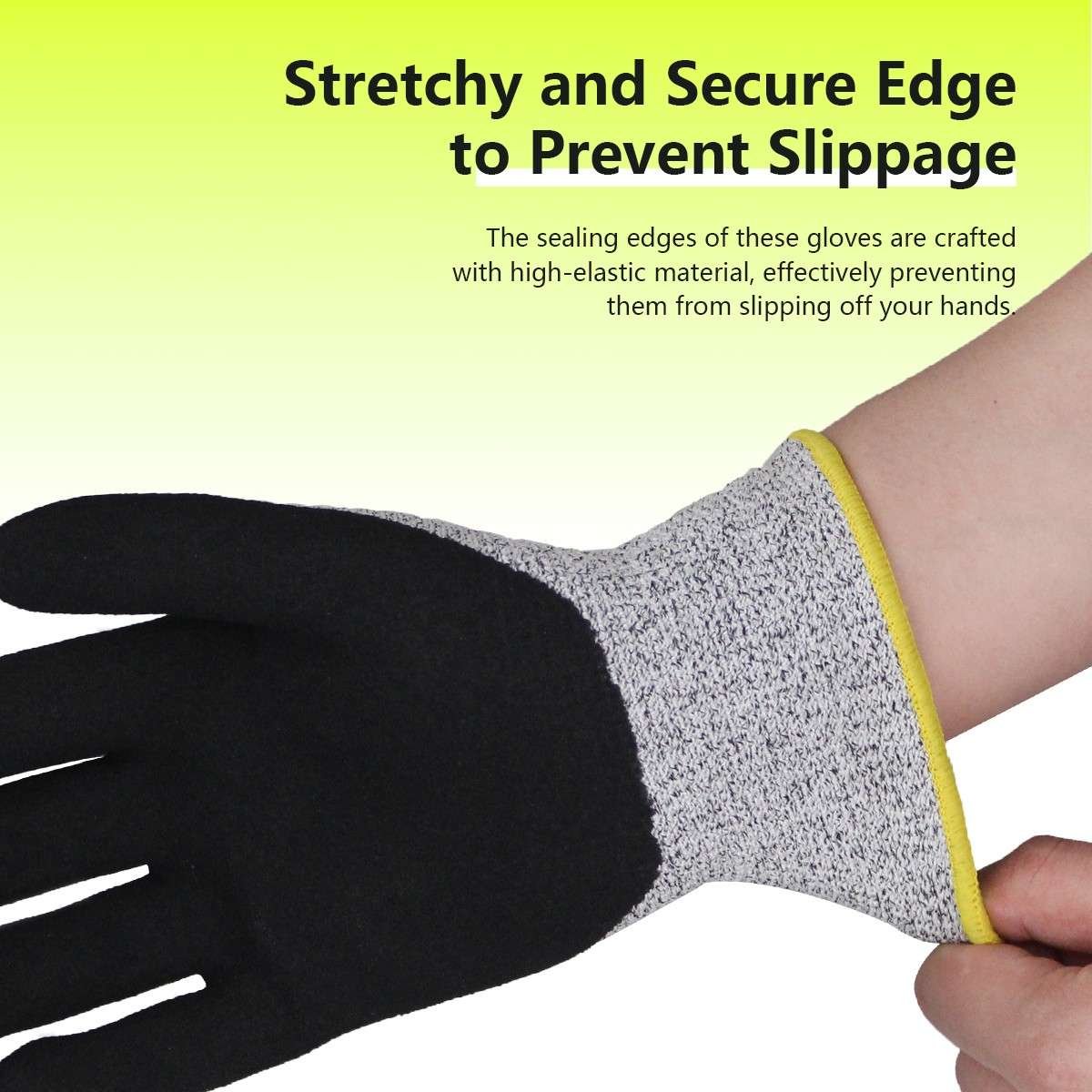

10. **Elastic and firm edges**: the gloves are designed with elastic and firm edges to prevent slipping and ensure stable wear.

11. **Naturally breathable**: The breathability of the material keeps the gloves dry and cool when worn for long periods of time.

12. **Knitted Wrist**: The knitted wrist design helps prevent dust and debris from entering the glove, providing extra protection.

13. **Flexible**: The flexibility of the gloves makes them suitable for a variety of delicate operations, enhancing work efficiency.

14. **Ergonomic**: The gloves are ergonomically designed to reduce hand fatigue and enhance wearing comfort.

15. **Comfortable to wear**: soft materials and fine production technology to ensure that the gloves are comfortable to wear, not easy to cause skin discomfort.

S1012N cut resistant gloves are suitable for a wide range of industries and working environments, including but not limited to

– **Gas industry**: during the installation and maintenance of gas equipment, the gloves provide the necessary protection against hand injuries.

– **Repair shop**: When repairing automobiles and mechanical equipment, it is especially important for gloves to be oil-resistant and slip-resistant.

– **Electronics industry**: the dexterity and protective properties of the gloves make them suitable for assembly and repair work on electronic components.

– **Automotive industry**: Gloves provide comprehensive hand protection during automotive manufacturing and repair.

– **Horticultural industry**: the abrasion resistance and anti-slip properties of the gloves make them suitable for a wide range of operations in horticultural work.

– **Paper industry**: the cut and abrasion resistance of the gloves provide the necessary protection during paper and paper product processing.

– **Kitchen**: the slip resistance and oil resistance of the gloves make them suitable for a variety of operations in the kitchen environment.

– **Construction**: the gloves provide total hand protection during construction sites and building construction.

– **Manufacturing industry**: the abrasion and tear resistance of the gloves make them suitable for a variety of operations in the manufacturing industry.

– **Warehousing industry**: gloves provide essential protection during warehouse management and goods handling.

– **Butchery and processing**: the cut and oil resistance of the gloves makes them suitable for butchery and meat processing work.

– **Wood carving industry**: gloves provide essential hand protection during wood carving and carpentry operations.

– **Machine manufacturing industry**: the abrasion and tear resistance of the gloves make them suitable for machine building and maintenance work.

– **Glass Handling**: the cut resistance of the gloves provides the necessary protection during glass cutting and handling.

– **Sheet metal working**: the cut resistance and abrasion resistance of the gloves make them suitable for sheet metal working.

– **Military Tactical**: the gloves’ durability and protection make them suitable for military tactical operations.

– **Safety guard**: the protective properties and dexterity of the gloves make them suitable for safety guard work.

– **Diamond Processing**: the gloves provide essential hand protection during diamond and gemstone processing.

– **Silicon Processing**: the cut and abrasion resistance of the gloves makes them suitable for work with silicon materials.

– **Automotive shipbuilding**: the gloves provide comprehensive hand protection during automotive and shipbuilding processes.

– **Handling, steel plate finishing**: the gloves’ abrasion resistance and slip resistance make them suitable for handling and steel plate finishing work.

– **Assembly work**: the dexterity and protective properties of the gloves make them suitable for a wide range of assembly work.

– **Metal working**: the cut resistance and abrasion resistance of the gloves make them suitable for metal working.

– **Precision grinding**: the gloves provide essential hand protection during precision grinding and polishing.

– **Cargo handling**: the gloves’ abrasion resistance and anti-slip properties make them suitable for cargo handling work.

– **Metallurgy**: the gloves provide comprehensive hand protection during metallurgy and metal working processes.

– **Automotive maintenance**: the gloves’ oil resistance and anti-slip properties make them suitable for automotive maintenance work.

– **Wildland protection**: the gloves’ durability and protective properties make them suitable for wildland protection and disaster relief work.

The S1012N Cut Resistant Glove is a versatile, high-performance hand protection gear for a wide range of industries and work environments. Its excellent cut resistance, abrasion resistance, slip resistance and comfort make it the best choice for hand protection. Whether in industrial production, maintenance, or daily work, the S1012N Cut Resistant Gloves provide reliable protection and a comfortable wearing experience. If you are looking for a high-quality protective glove, the S1012N Cut Resistant Gloves are undoubtedly your ideal choice.

Product parameters

| Model Number | Unit | Manufacturing Technique | Gauge | Meterials | Coating | Color of Coating | Size | Color | Features | Performance | Cuff Tightness |

|---|---|---|---|---|---|---|---|---|---|---|---|

| S1012N | Pair | Seamless knitting/Dipping | 13 | HPPE/Nitrile | Nitrile | Black | 6-12 | Grey/Customized | Cut Resistance Tear Resistance Abrasion Resistance Anti-slip Oil resistance High elasticity | ISO13997 : Level C ANSI: A3 | Elastic cuff |

About us

As a manufacture of safety products, SIZA Safety focus on the development of high quality cut resistant and flame-retardant PPEs more than 14 years in these fields. SIZA Safety targets to offer the most reliable and the most comfort solutions against cut and heat hazards of different industries. SIZA Safety cut resistant and flame -retardant PPEs are all specialized for good balance of blade resistance, heat resistant and comfort, to make sure our customers can be well protected when wearing our products, as the same time feeling good.

Our team

Our team brings together passionate and dedicated experts in the field of textiles, who have extensive experience and deep understanding of the industry. We always adhere to the principle of integrity-based, standardized operation and efficient execution, and are committed to providing customers with high-quality OEM and ODM products and services. No matter what your needs are, we can tailor efficient and fast solutions for you, so that you have no worries. Choose us, is to choose professional and trust, let us work together to create a better future!